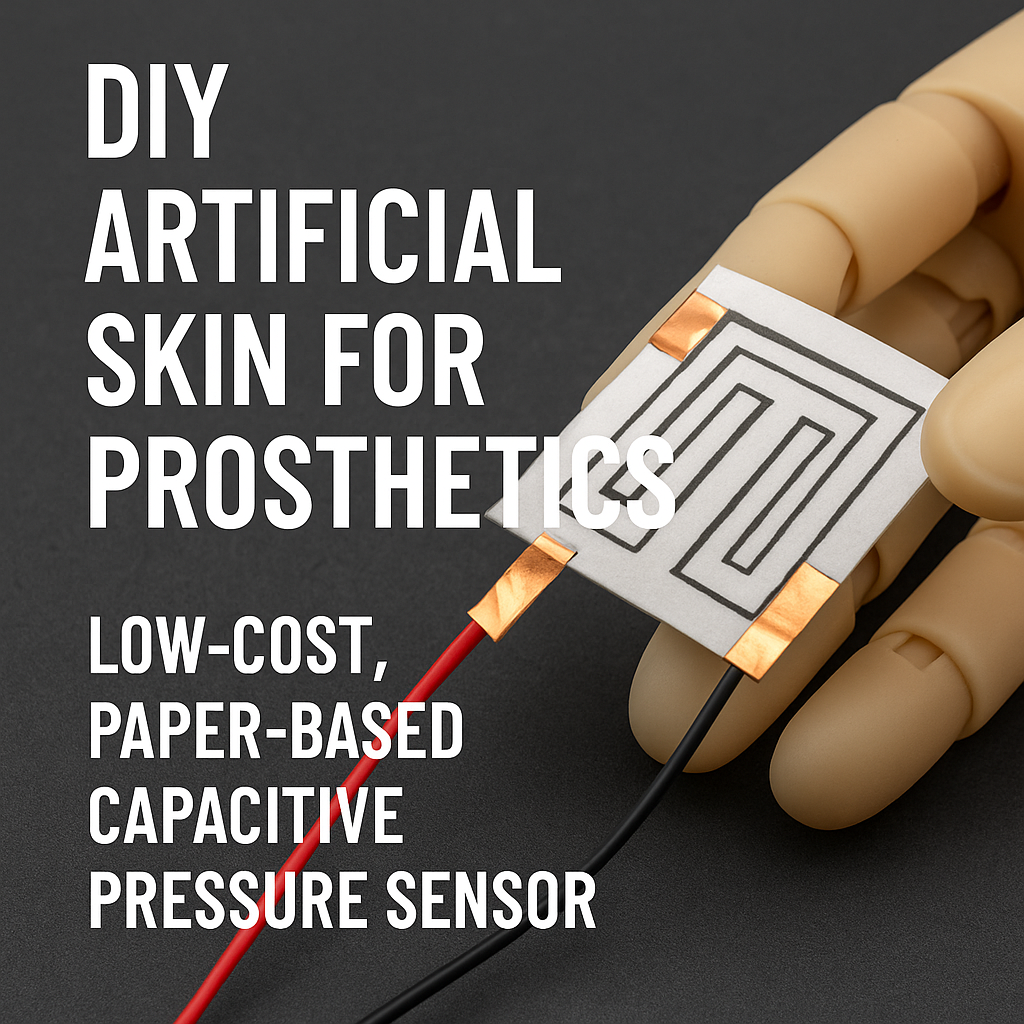

Introduction: DIY Artificial Skin for Prosthetics

DIY Artificial Skin for Prosthetics is one of the most revolutionary trends in 2025 for hobbyists, engineers, and innovators. Today, engineers have created a low-cost, paper-based capacitive pressure sensor that mimics the touch sensitivity of human skin.

This breakthrough is changing the future of robotics, wearable technology, and prosthetic devices by offering affordable and flexible tactile sensing solutions.

In this blog post, we will explore the materials, methods, benefits, and how you can build your own DIY artificial skin for prosthetics at home.

What is DIY Artificial Skin for Prosthetics?

DIY Artificial Skin for Prosthetics is a handmade, low-cost solution designed to replicate the tactile sensing ability of human skin. It involves building a flexible, pressure-sensitive sensor using everyday materials like paper, conductive ink, and a microcontroller such as Arduino or ESP32.

This artificial skin can detect even slight changes in pressure, enabling prosthetic hands and robotic arms to sense touch just like real human limbs.

Key Breakthrough:

Instead of relying on costly nanomaterials or high-end fabrication, this artificial skin can be built with materials accessible to hobbyists, researchers, and developers worldwide.

Why DIY Artificial Skin for Prosthetics Matters

1. Affordable Tactile Sensing

Traditional artificial skins are expensive and complex. However, DIY artificial skin for prosthetics offers a highly affordable way to integrate tactile feedback into devices.

2. Accessibility for Hobbyists

Anyone with basic electronics skills can now explore building touch-sensitive prosthetic hands or smart robotic systems using this low-cost technology.

3. Human-Machine Interaction

DIY artificial skin greatly enhances how prosthetics and robotics interact with the world by sensing pressure, improving grip control, and delivering more human-like performance.

How DIY Artificial Skin for Prosthetics Works

The heart of the technology is a paper-based capacitive pressure sensor.

Materials Needed:

- A4 paper

- Conductive ink or graphite pencil

- Double-sided foam tape

- Copper tape

- Microcontroller (Arduino/ESP32)

Working Principle:

- Two conductive electrodes are drawn on paper sheets.

- A dielectric spacer (tape or foam) separates them.

- When pressure is applied, the distance between electrodes changes, altering capacitance.

- The change in capacitance is read by the microcontroller to measure the pressure.

DIY artificial skin for prosthetics is incredibly sensitive, affordable, and flexible, making it ideal for both simple and complex projects.

Why It Works:

- Capacitance (C) is inversely proportional to the distance between the electrodes.

- More pressure = Less distance = Higher capacitance = Detectable change.

This method is highly sensitive, lightweight, eco-friendly, and cheap—ideal for scalable prosthetics and robotics.

DIY Project: Build Your Own Paper-Based Tactile Sensor

If you’re a maker or a hobbyist, you’ll love this part! Here’s a simplified guide on creating your own artificial skin sensor.

Materials Needed:

Regular A4 paper

Conductive ink pen or 4B/6B pencil

Double-sided foam tape

Scissors

Copper tape

Arduino Nano or ESP32 board

Breadboard and jumper wires

Advantages of DIY Artificial Skin for Prosthetics

- Create Electrodes

Draw two separate rectangles using the conductive pen or dark graphite pencil on two sheets of paper. - Prepare the Dielectric Layer

Cut a piece of double-sided foam tape the same size as the electrodes. Place it between the two conductive sheets. - Assemble Layers

Stack the papers: electrode layer, foam tape (dielectric), second electrode. - Connect Wires

Attach copper tape to each electrode for wiring to the microcontroller. - Program the Microcontroller

Use Arduino code to read capacitance changes through analog or capacitive sensing libraries. - Test Pressure Sensitivity

Gently press the sensor and observe how values change depending on force intensity.

Tip: You can chain multiple sensors to create a full artificial skin matrix for robotic arms or prosthetic hands.

Applications of DIY Artificial Skin for Prosthetics

The possibilities for this innovation are endless. Some powerful applications include:

Advanced Prosthetic Hands

Allow users to feel pressure, weight, and even roughness.

Improve grip control for objects of varying fragility.

Potential integration with haptic feedback motors to simulate touch.

Smart Robotics

Robots can gently handle objects without damaging them.

Agricultural robots can harvest delicate fruits.

Medical robots can assist in surgeries requiring sensitive touch.

Wearable Tech

Pressure-sensitive gloves for gaming, VR, and AR applications.

Health-monitoring wearables that detect pulse or swelling.

Gesture-controlled smart textiles.

Educational Tools

Perfect low-cost project for students learning about sensor technology, capacitive systems, and robotics.

Advantages of DIY Artificial Skin for Prosthetics

| Feature | Benefit |

|---|---|

| Low Cost | Materials cost under $5 per sensor. |

| Easy Fabrication | No specialized lab equipment needed. |

| Flexibility | Perfect for curved surfaces like hands and arms. |

| Eco-Friendly | Biodegradable base materials. |

| High Sensitivity | Detects a wide range of pressure levels. |

| Scalability | Can build arrays for full tactile skins. |

Challenges in DIY Artificial Skin for Prosthetics

Of course, like any DIY technology, there are trade-offs:

- Durability: Paper isn’t waterproof or highly wear-resistant.

- Temperature Sensitivity: Extreme heat or moisture can affect performance.

- Calibration Complexity: Scaling to hundreds of sensors needs advanced calibration.

Solutions:

Use laminated coatings for waterproofing.

Develop software calibration routines.

Shift to hybrid materials (textiles, flexible plastics) for rugged use cases.

Future Trends in DIY Artificial Skin for Prosthetics

Looking ahead, innovations in DIY artificial skin include:

- Stretchable Materials: Flexible circuits that move like human skin.

- Self-Healing Sensors: Materials that automatically repair small cuts and tears.

- Multi-Sensing Skins: Integrating pressure, temperature, and humidity sensing in one layer.

- Wireless Communication: Sensors that send tactile data via Bluetooth or WiFi to external devices.

DIY artificial skin for prosthetics is just the beginning. Future designs could create prosthetic limbs that feel indistinguishable from biological ones!

Impact on Prosthetics: Empowering Lives

For amputees, traditional prosthetics often feel “lifeless” due to lack of feedback. Integrating artificial skin with tactile sensing will:

- Restore a sense of touch.

- Enable fine motor control.

- Improve emotional connection to the prosthetic.

This technology could profoundly impact rehabilitation, confidence, and daily quality of life for millions worldwide.

And with a low-cost DIY option, accessibility improves for underserved populations globally.

Conclusion

DIY Artificial Skin for Prosthetics is more than a maker project—it’s a transformative technology.

Thanks to affordable, paper-based capacitive pressure sensors, anyone can build prosthetics and robotics that feel the world around them. The best part? All you need is paper, conductive ink, simple electronics, and a passion for innovation.

Start experimenting today with your own DIY artificial skin projects, and become part of a future where machines can touch, feel, and interact just like us!

Articles You Might Enjoy:

Top 10 Innovations Billion Dollars Buisiness

Top 10 DIY Electronics Projects for College Students in 2025

Raspberry Pi: A Complete Guide

External Links

https://en.wikipedia.org/wiki/Limbitless_Solutions